Custom injection mold making for US companies

70% injection molds made by ACO MOLD are exported to US or European companies, these injection molds are usually required to be SPI Class 101, guaranteed 1 million cycles or more, mold standard apply to US or Euro local standard so it can be easily operated and maintained.

Comparing with stay-in-house-molding mold, the export mold requires a higher capability to mold maker on not just how to make the injection molds but also how to work with US companies. Here we share with you a custom mold making project we have done in our factory, we are sure there would be much more on somewhere we can do much better and achieve much more satisfaction, we summarize it, look back and move forward for better and better customized mold projects made in China by ACO MOLD.

Basic Information

This information list here give the customer a good view to understand some basic information about the plastic part, color, finishing, etc as well as the basic idea of the injection mold such as mold steel, mold structure, mold standard etc. you will have a good start by cross check these information with us.

Get injection molding machine specification from the customer and make the mold applied to the machine

Unlike a stay-in-house mold, a qualified export custom mold must be applied to the customer's machine and run smooth in customer's molding shop. So first of everything, we confirm this information with the customer, sometimes it means we need to customize the mold base size to fit it in.

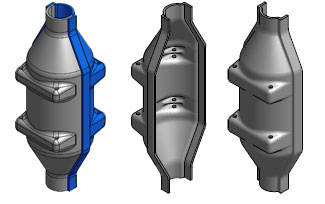

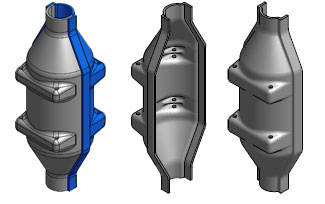

Do a draft design and confirm with customer about mold design before 3D construction.

Start 2D/3D mold design

After all the pre-design discussion, we started 2D/3D mold design, usually it will be done in 2-3 working days.

Mold Making and Progress Report

After mold design confirmed, we start making the injection mold in our factory, it takes 5 weeks to complete this harden mold, during mold making, we updated once a week to keep the customer updated by progress report, so our customer can just sit back and cross fingers to wait the due date.

Mold Test and Film the Test Video

Most of ACO MOLD customers are from North America & Europe, it's a far way and high expenses for the companies go to China to witness the mold test in our factory, but we think it's just, our mold engineers on site would be there and film the most test running for your companies. So after mold test finished, our customer would not just receive samples but also mold test injection parameters, measurement reports, and mold test videos.

Mold on machine

Samples

Injection Parameters

Video of Mold Testing

Mold Packing and Shipping

Thorough pre-design discussion, a great mold design and excellent mold making capacity. We think these 3 factors are the key to achieve high quality, competitive pricing, fast turn around for an injection mold making project. Usually we do 1 or 2 times mold test before shipping out of our factory.

The injection mold will be packed with film to prevent air, along with the mold, we will also ship the customer all the mold design data/NC program data, and certificate of all the steel and mold base we used.

Comparing with stay-in-house-molding mold, the export mold requires a higher capability to mold maker on not just how to make the injection molds but also how to work with US companies. Here we share with you a custom mold making project we have done in our factory, we are sure there would be much more on somewhere we can do much better and achieve much more satisfaction, we summarize it, look back and move forward for better and better customized mold projects made in China by ACO MOLD.

Basic Information

This information list here give the customer a good view to understand some basic information about the plastic part, color, finishing, etc as well as the basic idea of the injection mold such as mold steel, mold structure, mold standard etc. you will have a good start by cross check these information with us.

Get injection molding machine specification from the customer and make the mold applied to the machine

Unlike a stay-in-house mold, a qualified export custom mold must be applied to the customer's machine and run smooth in customer's molding shop. So first of everything, we confirm this information with the customer, sometimes it means we need to customize the mold base size to fit it in.

Do a draft design and confirm with customer about mold design before 3D construction.

Start 2D/3D mold design

After all the pre-design discussion, we started 2D/3D mold design, usually it will be done in 2-3 working days.

Mold Making and Progress Report

After mold design confirmed, we start making the injection mold in our factory, it takes 5 weeks to complete this harden mold, during mold making, we updated once a week to keep the customer updated by progress report, so our customer can just sit back and cross fingers to wait the due date.

Mold Test and Film the Test Video

Most of ACO MOLD customers are from North America & Europe, it's a far way and high expenses for the companies go to China to witness the mold test in our factory, but we think it's just, our mold engineers on site would be there and film the most test running for your companies. So after mold test finished, our customer would not just receive samples but also mold test injection parameters, measurement reports, and mold test videos.

Mold on machine

Samples

Injection Parameters

Video of Mold Testing

Mold Packing and Shipping

Thorough pre-design discussion, a great mold design and excellent mold making capacity. We think these 3 factors are the key to achieve high quality, competitive pricing, fast turn around for an injection mold making project. Usually we do 1 or 2 times mold test before shipping out of our factory.

The injection mold will be packed with film to prevent air, along with the mold, we will also ship the customer all the mold design data/NC program data, and certificate of all the steel and mold base we used.